By William Miller. Published in the N-News summer 2023 issue, Volume 38 Number 3

When my father retired as a captain with the sheriffs department, he sold his home in San Jose and moved to Tracy, CA to enjoy the farm life. He bought a place that had a 2-acre walnut grove on it. His first tractor was a Ford Diesel 2000 (also known as Super Dexta). He bought a 1980 project tractor, a Ford 3600 Narrow Orchard model and completely restored it. He had been restoring 1940s, 1950s and 1960s Ford cars and trucks in his 1800 sf shop behind his home, so for him, it was just another restoration.

When my father retired as a captain with the sheriffs department, he sold his home in San Jose and moved to Tracy, CA to enjoy the farm life. He bought a place that had a 2-acre walnut grove on it. His first tractor was a Ford Diesel 2000 (also known as Super Dexta). He bought a 1980 project tractor, a Ford 3600 Narrow Orchard model and completely restored it. He had been restoring 1940s, 1950s and 1960s Ford cars and trucks in his 1800 sf shop behind his home, so for him, it was just another restoration.

After my father passed away in 2013, and after a year of living alone, my step-mother decided to sell the farm. I told her I was interested in buying the house and farm and she sold it to me. (She’s currently enjoying her retirement in Hawaii.) I knew nothing about farming, so I continued using her gardener who takes care of the 3.7 acre property. He would periodically plow the 2-acre field with the Ford 3600 tractor when weeds started to grow.

After my father passed away in 2013, and after a year of living alone, my step-mother decided to sell the farm. I told her I was interested in buying the house and farm and she sold it to me. (She’s currently enjoying her retirement in Hawaii.) I knew nothing about farming, so I continued using her gardener who takes care of the 3.7 acre property. He would periodically plow the 2-acre field with the Ford 3600 tractor when weeds started to grow.

A couple years into owning the farm, I got more interested in the tractor and he taught me how to drive it. I saw how useful the 3600 was, to plow, to grade, to flatten the 500-foot gravel driveway with a steel roller, to drill holes with the 3-point auger and to lift with a shallow forklift. I had wished it also came with a front loader. So, I started looking for a loader to attach to the 3600. That was when my tractor hobby/collection took off like crazy.

And that’s how I met Harold, the 90 year-old previous owner of the Blackwelder Forklift.

I would often drive past Harold’s house as we both live on the same street, about 1.5 miles apart, but we were strangers at that time. It was not until I got interested in tractors that I noticed his property had a lot of old tractors on it. Once you get into tractors, you develop “tractor eyes” and that pretty much opens a whole new world when you are out driving around anywhere. I decided to knock on Harold’s door.

I asked if he was interested in selling any of the tractors and we became friends. When I saw the 8N with the Blackwelder forklift on the back, I asked if he was willing to sell it but he said no. He asked if I could fix one of his tractors, saying that the distributor was bad. I took it off, brought it home, took it apart and rebuilt it for him and then put it back on. Tractors can make new friends!

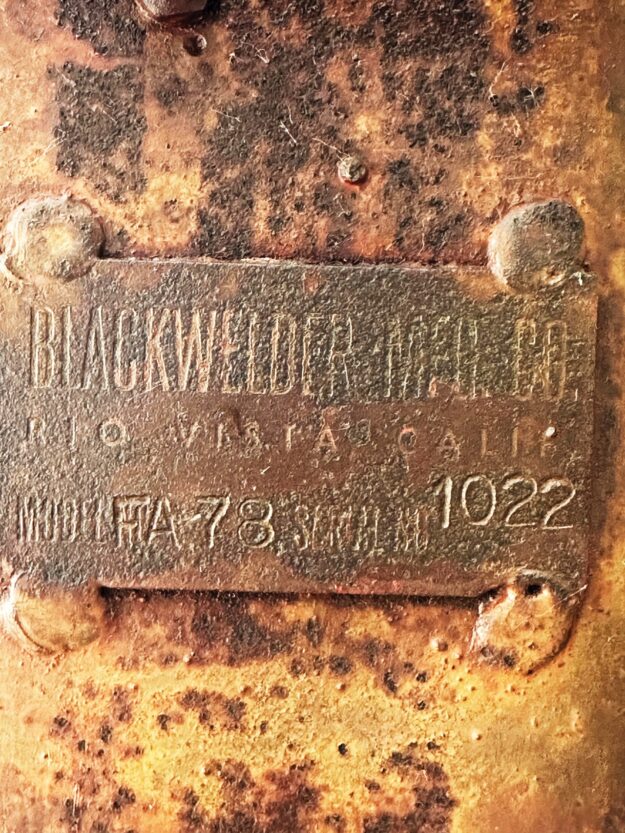

After a few years went by, he told me he was ready to sell the 8N-Forklift. That was last month. I am looking forward to bringing it back to life. I plan to use the forklift to load stuff on/off my truck as my current “forklift” is a 3-point and does not lift more than a couple feet. Harold said he bought it used in 1960. I happen to live an hour south of Rio Vista, where Blackwelder Manufacturing was based.

After a few years went by, he told me he was ready to sell the 8N-Forklift. That was last month. I am looking forward to bringing it back to life. I plan to use the forklift to load stuff on/off my truck as my current “forklift” is a 3-point and does not lift more than a couple feet. Harold said he bought it used in 1960. I happen to live an hour south of Rio Vista, where Blackwelder Manufacturing was based.

I started with only the 3600 and now I’m up to nine tractors. I found the 1941 Ford 9N being advertised on Facebook. It was only an hour away; I brought my first project tractor home. As I was shopping for original parts, I kept finding more N-tractors that the present generation wanted off their properties. I had a lot of luck getting great tractors for very cheap. I live in the Central Valley farming country, so there are plenty of abandoned tractors. I recently found a 1939 9N – SN4170, all complete with 12V. I will restore it back to the original 6V. It needs to be painted in the correct color as well.

I started with only the 3600 and now I’m up to nine tractors. I found the 1941 Ford 9N being advertised on Facebook. It was only an hour away; I brought my first project tractor home. As I was shopping for original parts, I kept finding more N-tractors that the present generation wanted off their properties. I had a lot of luck getting great tractors for very cheap. I live in the Central Valley farming country, so there are plenty of abandoned tractors. I recently found a 1939 9N – SN4170, all complete with 12V. I will restore it back to the original 6V. It needs to be painted in the correct color as well.

Enjoy this article? Subscribe to the N-News Magazine for more essential N-News! Subscribers have made the print version of the N-News Magazine a success for over 30 years. Subscribe today!

Enjoy this article? Subscribe to the N-News Magazine for more essential N-News! Subscribers have made the print version of the N-News Magazine a success for over 30 years. Subscribe today!