By Dick Eyler. Published in the N-News Summer 2014. Vol. 29 No. 3.

The poles were 6×6’s twenty feet long. The metal trusses spanned thirty feet. I was building a pole barn to house tractors and combines at a peanut farm. Most of the work I’d do myself, but Fred Catabia, a friend, volunteered to help when he had time.

The first problem I needed to solve was how to set the heavy posts and install the metal trusses. Fred recalled that I had a Ford tractor with a front end loader. He explained how to build a “Truss Boom” for the loader and volunteered to do the work if I brought the tractor by his shop.

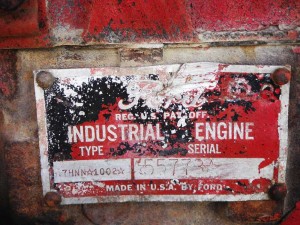

The tractor was an 8N with a Funk conversion using a 6 cylinder Ford industrial engine. It had a vintage front end loader. I bought the tractor a number of years ago with the intention of restoring it but it seemed I always had a use for it – a project on the horizon I needed it for. It was rusty, there were oil leaks, the radiator leaked, the carburetor needed cleaning, and hydraulic hoses on the front end loader were cracked with age and needed replacing. However, with new spark plugs it ran good enough for one more job before I started work on it.

The main arm of the Truss Boom was constructed from a scrap piece of 7 inch channel iron. It was cut to a 15 foot length. A hole was drilled in one end for a ¾ inch bolt, which would fasten it to the lower lip of the bucket on the front end loader. On the far end a hole was cut so chain could be threaded through the boom to attach the truss or pole. To stabilize the boom a piece of 5⁄16 inch chain was attached on each side from the bucket to a 2 foot cross bar welded just past midway on the boom. The width of the bucket on this loader was only 3 feet, so a 5 foot bar was bolted to the top lip of the bucket for additional stability to attach chains.

The boom worked perfectly. The poles were lifted by wrapping a piece of nylon webbing around each pole and chaining this to the boom. Trusses were chained directly to the boom.

Using the hydraulic controls of the front end loader, it was easy to be precise placing the poles in the holes and setting the trusses on top of the poles. The Ford Funk tractor and the Truss Boom made what I thought would be a difficult job easy, even for one person.

Enjoy this article? Subscribe to the N-News Magazine for more essential N-News! Subscribers have made the print version of the N-News Magazine a success for 30 years. Pick one up today!

Enjoy this article? Subscribe to the N-News Magazine for more essential N-News! Subscribers have made the print version of the N-News Magazine a success for 30 years. Pick one up today!